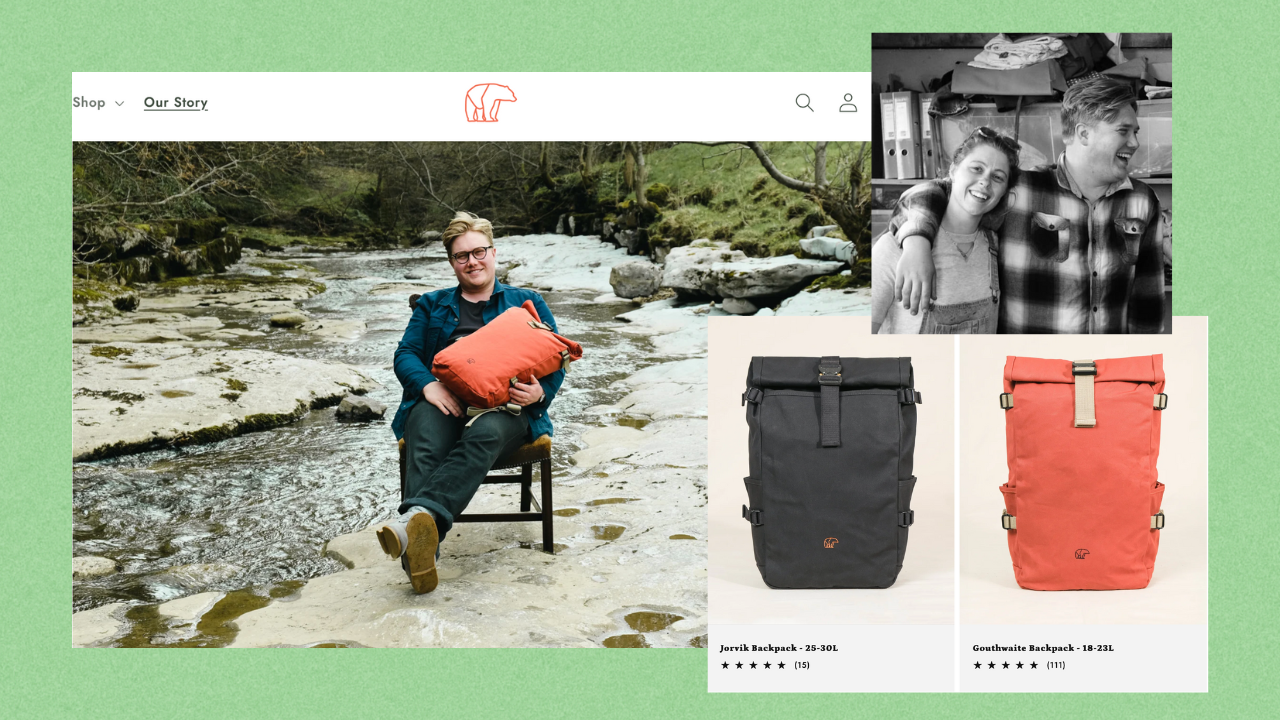

How Wildish is building a resilient Glocal business

Sep 25, 2025

With everything going on in the world, you might find yourself craving a trip into nature. Before heading out, you stop by an outdoor store—only to realize the industry is overflowing with gear. Much of it is cheaply made, designed for short-term use rather than long-term durability.

Wildish takes a different approach. They limit production, prioritize small-scale, local manufacturing, and design for longevity.

Instead of chasing volume, they make just 25 bags a week.

Their vision?

To have local bag makers worldwide, crafting with materials native to their regions.

Strategy You Can Apply: The "Glocal" Model for Local Manufacturing

Instead of scaling through centralized mass production, Wildish aims to establish small local bag makers in different regions, producing bags from materials sourced within each area.

Most companies rely on complex, international supply chains, leading to long lead times, high emissions, and vulnerability to disruptions—whether from political instability, trade restrictions, or raw material shortages.

Wildish's approach could make them more resilient, socially beneficial and with a lower negative pressure on the environment.

Potential Benefits of This Strategy

- Resilient Supply Chains

- Dependence on global supply chains has proven risky—whether due to geopolitical conflicts, labor shortages, or raw material disruptions.

- A distributed network of local makers diversifies risk and ensures production even when global supply chains are strained.

- Stronger Local Economies

- Keeping production regional means jobs stay local and economic value remains within communities, instead of flowing to distant corporate headquarters.

- A decentralized model allows makers to tailor products to local needs and preferences, creating deeper customer connections.

- Lower Emissions from Transport & Logistics

- Today, most products travel thousands of miles before reaching the customer. By sourcing materials and manufacturing locally, businesses can significantly reduce carbon emissions from transportation of materials.

- Local production also shorten supply chains, reducing the environmental impact of gobal shipping to end-customer.

- Authenticity and Storytelling

- Local production adds authenticity. Customers know where their products come from, who made them, and what materials were used.

- This transparency builds trust and reinforces the company’s commitment beyond marketing claims.

3 Key Takeaways

- Strengthen local economies by keeping production in-region.

- Make supply chains more resilient to disruptions.

- Reduce emissions from global shipping.

Challenges and Considerations

While the benefits are clear, local production can come with challenges:

- Higher costs: Sourcing regional materials is often more expensive than bulk global suppliers.

- Quality control: Ensuring consistent quality across multiple local workshops can be complex.

- Scaling limitations: A decentralized model requires strong partnerships and knowledge-sharing among regional makers.

How Businesses Can Apply This Strategy

- Identify opportunities for regional production—whether in manufacturing, assembly, or sourcing raw materials locally.

- Test local production with pilot projects in key markets rather than shifting entirely at once

- Use digital platforms to connect customers with locally made versions of the same product.

Open Question: Does the World Need More?

Does the world need more outdoor bags, gear, and apparel?

One could argue no—manufacturers already produce billions of clothing items each year. (For reference, Adidas alone made 900 million products last year.)

One could also argue yes—because most of what’s produced today is too low-quality to last, even with proper care. The problem isn’t that new products exist—it’s that most of them aren’t designed to endure.

Size and Scale

Wildish is small—and by design, they intend to stay that way. Their model challenges the idea that success means unlimited growth. Instead of prioritizing volume, they focus on value per unit produced—emphasizing quality, repairability, and local economic impact.

What if more businesses followed this path?